Add to Cart

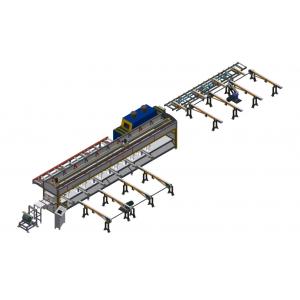

Automatic bagging equipment

1. Equipment structure

Main frame of bagging machine (7.11KW): The main frame is welded by 100*100/50*5 steel square pipes. The three 9-meter-long longitudinal guide rails inside the structure are precisely processed by the gantry milling machine. Most of the non-standard spare parts Mainly adopt aluminum beams and aluminum plates through computer gongs, lathes, milling machines, wire cutting equipment and other precision grinding, drilling, milling, grinding and other processes to ensure the stable performance of the equipment during high-speed operation. The power part is driven by branded servo and speed-regulating motors and driven by cylinders to ensure the accuracy of equipment operation and the stability of control. The motor power is: 3.0KW*1, 1.5KW*1, 0.12KW*3.

2. PVC bag feeding frame

The main function is to send PVC/PE bags to the bagging machine at a fixed length, reduce the resistance of the bagging process, and realize the simultaneous progress of the bag feeding and bagging process. It is suitable for PE/PVC.

3. PVC bag opening heat shrinking system (11KW)

In the traditional bagging method, it is necessary to manually use the wrapping film to tie the PVC bag mouth firmly. Now, the automatic heating and shrinking sealing method is used to reduce manual operations and improve work efficiency. The heating oven adopts side-inserted metal far-infrared heating tubes and imported brand high-temperature-resistant high-speed fans, which have the characteristics of fast heating and good heat preservation effects. Function.

4. Automatic pick-up and feeding rack (0.75KW)

The material that has been heated and shrunk at the bag mouth is automatically sent to the power roller frame by the mechanical arm, and the material wrapped in the PVC bag is automatically sent to the heat shrinking machine through the power roller frame for profile The heating and shrinking packaging work can reduce the manual operation.

5. Automatic lifting rack (0.87KW)

The automatic picking rack equipped with computer automatic control system automatically transports the heated and shrink-wrapped profiles to the storage translation rack through the power felt roller and felt conveyor belt.

6. Fluent storage device

The fluent strip adopts square tube welded beams, and is equipped with independently disassembled and assembled nylon solid rollers, which are arranged in a staggered manner, so that the profiles can slide smoothly and slowly, with good load-bearing and durable. The storage capacity is large, which is convenient for manual framing and other turnover.